LB Series asphalt batch mixing plant is stationary type batch mixing asphalt plant,featured by high efficiency arge output, precise measurement and high quality ;finished asphalt, fit for road construction projects in all Model and Parameter grades and scales;especially for large-scale and high- grade road construction project.

| Model | LB1000 Asphalt mixing plant;H.S number: 84743200 |

|---|---|

| Type | Forced Periodic / Hot |

| Yield | 80ton/hour (standard work condition) |

| Mixer capacity | 1000kg/mixer |

| Diesel fuel | Consumption: 6.5-7.5kg/ (produce 1 ton asphalt concrete) |

| Weighing accuracy | Hot Minerals: ±0.5%; Bitumen: ±0.3%; Mineral powder: ±0.2% |

| Finished material temperature | 130℃-165℃ (can be adjusted) |

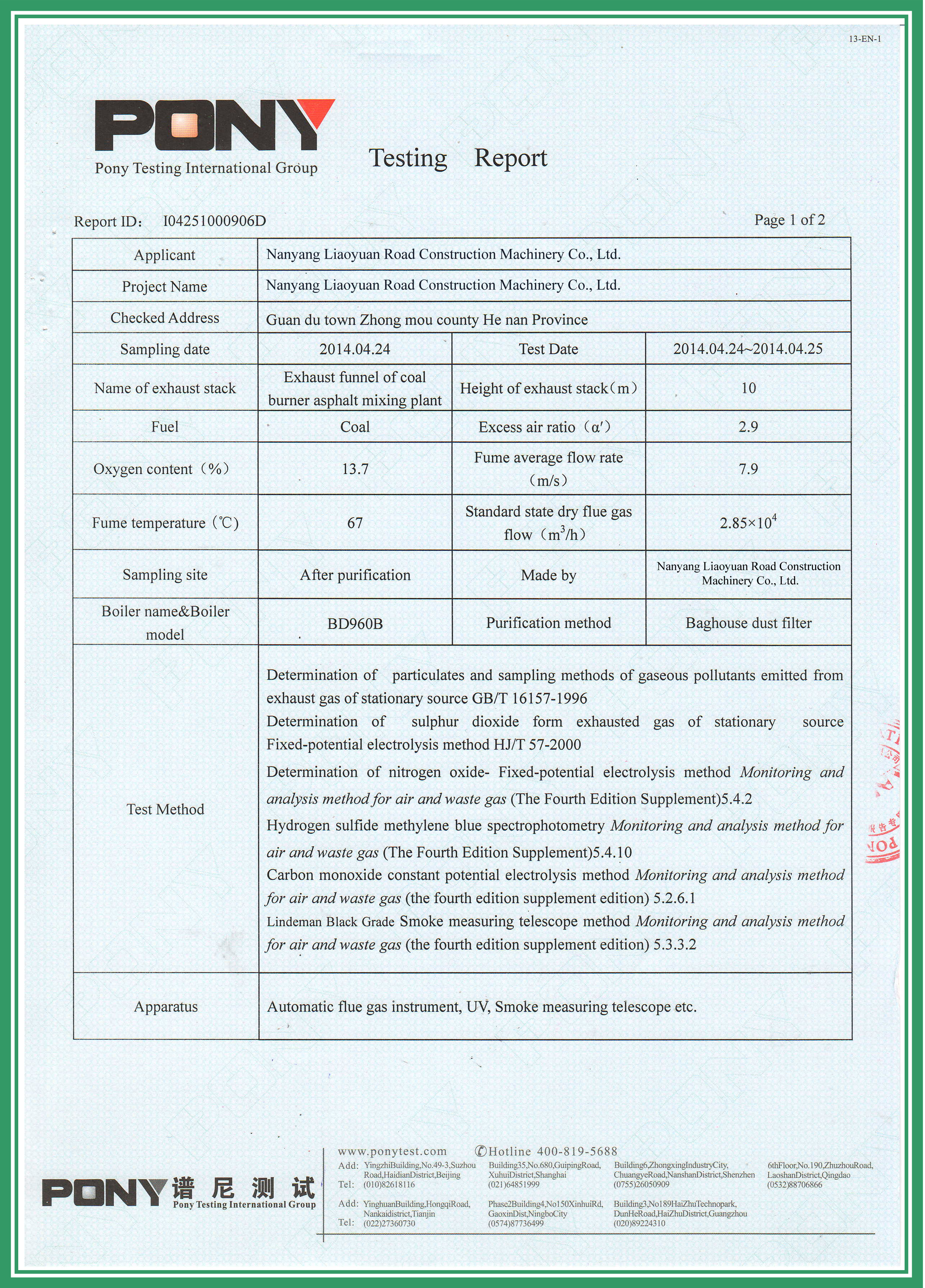

| Air pollution | ≤20mg/Nm³ |

| Noise | ≤70db(A) |

| Operate | Operation in fully automatic, semi-automatic and manual modes (can be switched) |

| Installed power | 264.07kw |

| Rated voltage | 220V/380V-50Hz (can be adjusted) |

| Floor space | Length : 38m; Width: 20m; Maximum height: 12.5m |

| Random document | General installation diagram; Foundation diagram ; Circuit diagram;Russian;Operation manual in Russian; Quality certifications |

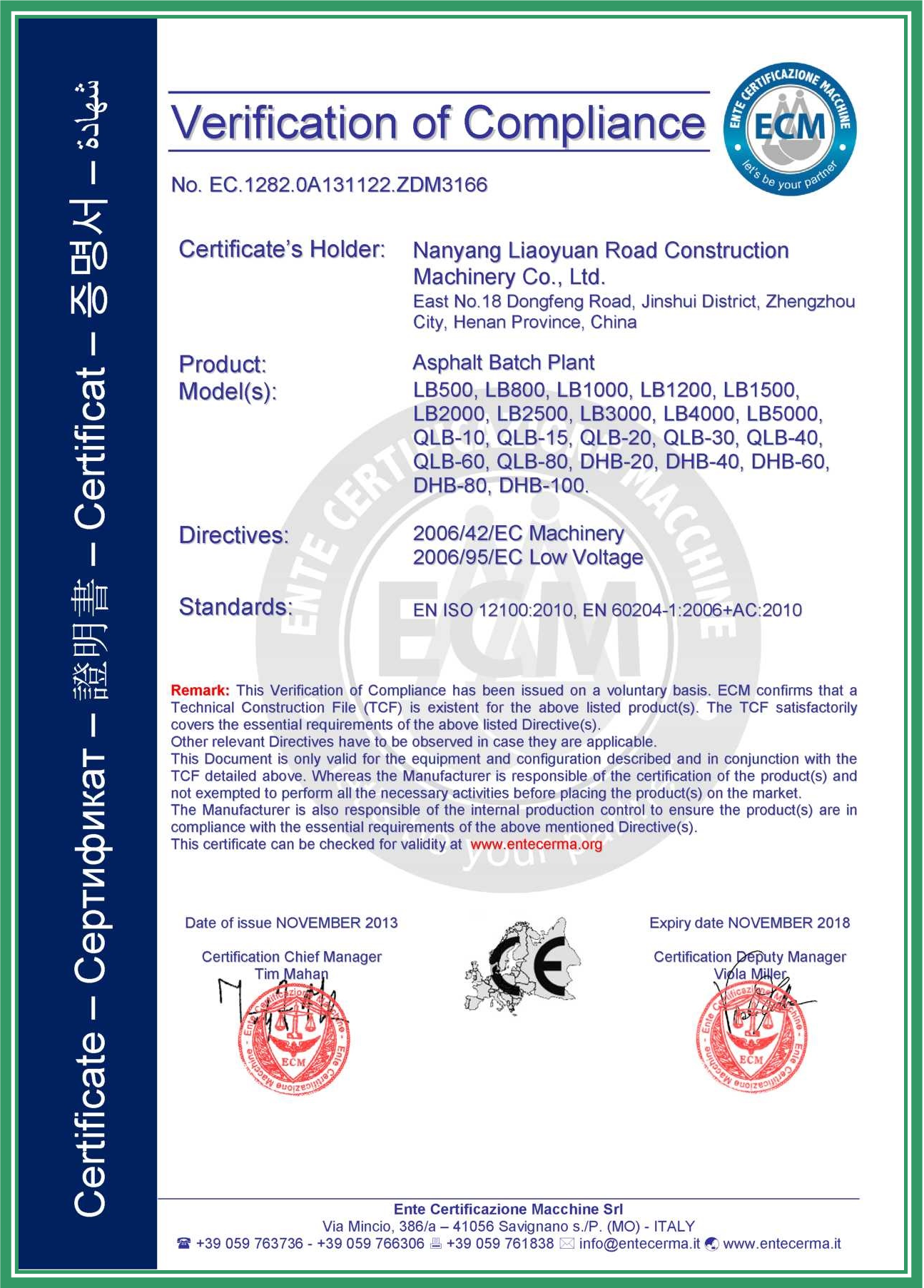

| Certificate | CE,EAC,ISO9001:2000 |

Certification